- Pigment for Color Masterbatch/Plastic

- Pigment for Water Based Ink

- Pigment for Solvent Based Ink

- Pigment for Offset Ink

- Pigment for Textile Printing Ink/Paste

- Pigment for Industrial Paint

- Pigment for Powder Coatings

- Pigment for Road Marking Paint

- Pigment for Automotive Paint/Refinish

- Pigment for Decorative Paint

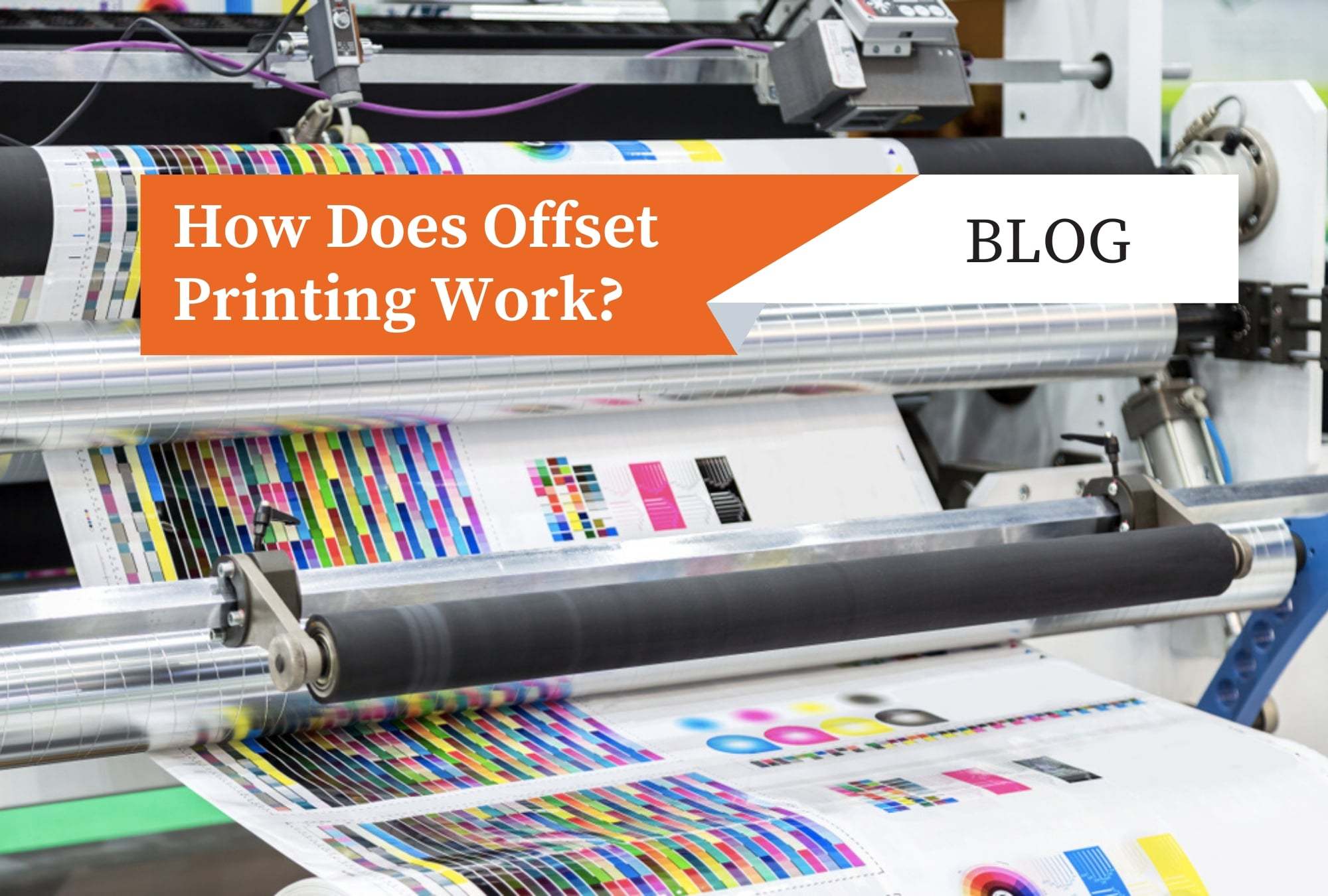

Pigment for Offset Ink

Offset ink is a specific type of ink used in conjunction with offset printing presses, such as those used to produce letterpress or lithography prints. Such ink must be specially formulated to resist other chemicals it will come in contact with on the printing press. It is widely used for printing high-quality images and text on various substrates such as paper, cardboard, and certain plastics.

It is crucial that offset ink resist water-in-ink emulsification (e.g., repel rather than absorb water). It also should withstand degradation by the fountain solution that covers the non-printing areas of the engraved plate. Offset ink needs to be very rich in pigment so that its full color vibrancy is perceptible, even in minute quantity.

There are many types of pigments used in the manufacture of offset printing inks. Organic pigments include insoluble azo pigments (such as Pigment Yellow 12, Pigment Yellow 14), azo lake pigments (such as Pigment Red 49:1, Pigment Red 53:1, Pigment Red 57:1), phthalocyanine pigments (such as phthalocyanine blue B-15:3, green G-7), heterocyclic pigments, etc.

- How Choose

- Customization

- Specification Table

- Why Choose

- Related Products

Color

Choose a color that matches the desired printing effect.the most widely used ink color is black. Then come cyan, magenta and yellow.

Gloss

It refers to an ink’s own ability to reflect light, and depends upon the lay or smoothness of the ink film on the substrate surface. Choose better gloss makes ink’s gloss better.

Particle size

Choose the appropriate size of pigment particles as it affects the oil Absorption of the ink and printing quality.

Flow

Make sure the paint has the best flow required, neither too long nor too short. Long-flow ink has good fluidity, short-flow ink has poor fluidity.

Strength

Choose suitable strength pigments to meet target budget.

Adaptability

Adaptability- √

High strength and gloss: Fineland pigments are High gloss, good adhesion,Very slow skinning performance on printing machine and excellent drying performance on printed materials, High press stability.

- √

Compatibility with other materials: Fineland pigments have strong compatibility with different resin and solvents, good resistant to water, alcohol and other chemicals.

Customization

Customization√ Provide small quantity customization services: If customers need small-scale production or rapid debugging of new products, we can provide small batch pigment customization services to help them obtain the required color samples in a short period of time.

- √

Customized solutions for different application areas: We can provide customized printing substrate to recommend suitable pigments, such as Offset paper (commonly known as Dowling paper), Coated paper, White board paper ,white newspaper and so on.

Technical Support

Technical Support- √

Provide printing process optimization suggestions: Based on customers' printing equipment and testing processes, we can provide corresponding technical support to help them optimize printing effects and production efficiency. Ensuring that they can fully leverage the advantages of pigments.

Color |

Product Name

|

Color Index

|

oil Absor ption

|

Strength[%]

|

Density [g/cm³]

|

Gloss

|

Specific Surface Area(m2/g)

|

Fluidity

| TDS |

MSDS

|

|

Full shade |

Tint shade |

||||||||||

Benzidine Yellow G | P.Y.12 | 45-50 | 100±5 | 1.40 | Excellent | 43 | Good | ||||

Benzidine Yellow 174 | P.Y.174 | 45-50 | 100±5 | 1.70 | Excellent | 20-63 | Good | ||||

Fast Yellow 5GXP | P.Y.74 | 45-50 | 100±5 | 1.28-1.51 | Excellent | 14 | Good | ||||

Permanent Yellow HR | P.Y.83 | 45-50 | 100±5 | 1.2-1.5 | Excellent | 49 | Good | ||||

Permanent Orange G | P.O.13 | 45-50 | 100±5 | 1.31-1.60 | Excellent | 12-42 | Good | ||||

Permanent Orange RL | P.O.34 | 45-50 | 100±5 | 1.3-1.4 | Excellent | 66 | Good | ||||

Bronze Red C | P.R.53:1 | 45-50 | 100±5 | 1.65-2.11 | Excellent | 7-110 | Good | ||||

Lithol Rubine 6B | P.R.57:1 | 45-50 | 100±5 | 1.42-1.8 | Excellent | 21-105 | Good | ||||

Quindo Red | P.R.122 | 45-50 | 100±5 | 1.40-1.50 | Excellent | 62 | Good | ||||

Fast Violet Toner | P.V. 3 | 45-50 | 100±5 | 2.15-2.30 | Excellent | 36-45 | Good | ||||

Permanent Violet RL | P.V. 23 | 45-50 | 100±5 | 1.40-1.60 | Excellent | 45-102 | Good | ||||

Carbon Black N330 | P.B.7 | 50 | 100±5 | 1.60 | Excellent | 102 | Good | ||||

Carbon Black FC2560 | P.B.7 | 62 | 100±5 | 1.70 | Excellent | 100 | Good | ||||

FINE BLACK641 | P.B.7 | 50 | 80±5 | Excellent | 42 | Good | |||||

FINE BLACK642 | P.B.7 | 62 | 130±5 | Excellent | 100 | Good | |||||

Color |

Product Name

|

Color Index

|

oil Absor ption

|

Strength[%]

|

Density [g/cm³]

|

Gloss

|

Specific Surface Area(m2/g)

|

Fluidity

|

TDS |

MSDS

|

|

Full shade | Tint shade |

||||||||||

Permanent Yellow 2GS | P.Y.14 | 45-50 | 100±5 | 1.14-1.52 | Excellent | 10-62 | Good | ||||

Benzidine Yellow G | P.Y.12 | 45-50 | 100±5 | 1.40 | Excellent | 43 | Good | ||||

Fast Yellow 5GXP | P.Y.74 | 45-50 | 100±5 | 1.28-1.51 | Excellent | 14 | Good | ||||

Benzidine Yellow 174 | P.Y.174 | 45-50 | 100±5 | 1.70 | Excellent | 20-63 | Good | ||||

Benzidine Yellow GR | P.Y.13 | 45-50 | 100±5 | 1.30-1.40 | Excellent | 10-62 | Good | ||||

Permanent Yellow HR | P.Y.83 | 45-50 | 100±5 | 1.2-1.5 | Excellent | 49 | Good | ||||

Permanent Orange G | P.O.13 | 45-50 | 100±5 | 1.31-1.60 | Excellent | 12-42 | Good | ||||

Permanent Orange RL | P.O.34 | 45-50 | 100±5 | 1.30-1.40 | Excellent | 66 | Good | ||||

Bronze Red C | P.R.53:1 | 45-50 | 100±5 | 1.65-2.11 | Excellent | 7-110 | Good | ||||

Lithol Rubine 6B | P.R.57:1 | 45-50 | 100±5 | 1.42-1.8 | Excellent | 21-105 | Good | ||||

Quindo Red | P.R.122 | 45-50 | 100±5 | 1.40-1.50 | Excellent | 62 | Good | ||||

Fast Violet Toner | P.V. 3 | 45-50 | 100±5 | 2.15-2.30 | Excellent | 36-45 | Good | ||||

Permanent Violet RL | P.V. 23 | 45-50 | 100±5 | 1.40-1.60 | Excellent | 45-102 | Good | ||||

- Fineland will try best to fully understand your pigment needs and concerns, providing targeted suggestions and information. Our sales team has relevant product knowledge with excellent service. Welcome to inquire from us! Contact us, find your reliable pigment supplier!

- contact us

| Image | Pigment for Offset Ink | Description | MOQ | More |

|---|---|---|---|---|

| Organic Pigment Yellow 12 | Premium Organic Yellow Pigment for Offset Ink - Your Trusted Wholesale Supplier | 1 | |

| Organic Pigment Violet 3 | Pigment Violet 3, strong bluish violet color, mainly recommend for printing ink. | 1 | |

| Organic Pigment Yellow 174 | PY174, new pigment in the recent market, high performance, it's good for offset ink. | 1 | |

| High Color Strength Factory Supply Price Good Quality Organic Pigment Green 7 for Coating/Plastic/Offset/Ink-Wholesale Supplier | Pigment Green 7, For Coating/Plastic/Offset/Ink | 1 | |

| Chinese Fcatory Wholesale PB 15:1 water-based pigment blue Pigment Blue Pigment Powder for Plastic and Coating | Wholesale PB 15:1 water-based pigment blue Pigment Blue 15:0 powder for Plastic and Coating | 1 | |

| wholesale factory price PB 15:0 water-based pigment blue CAS 147-14-8 Pigment Blue 15:0 powder for Plastic | wholesale factory price industrial grade PB 15:0 water-based pigment blue CAS 147-14-8 Pigment Blue 15:0 powder for plastic | 1 |

Consult Your Pigment Manufacturer

One of leading pigment manufacturers in China. We provide one-stop pigment solution, Make Sure high-quality and valuable pigment on time and on budget.

- *Name

- *Tel

- *Title

- *Content