Fineland Chem Factory Manufacturing

Master The Core Methods Of The Pigment Testing

Flat Grinder. It is mainly used to crush pigments into fine powder or paste for better dispersion and application in industries such as coatings, inks, cosmetics, etc.

Shaker Machine. It is a device commonly used for mixing and homogenizing pigments. It is mainly used for effective mixing and dispersion of pigments, fillers, and other additives.

Basic Testing

Usually test the pigment basic performance which applied in plastic and rubber.

Water based testing

Usually test the pigment property which applied in water based system like printing ink or paint.

Paint Testing

Usually test the pigment character which applied in solvent based coatings. Need to put it in the baking oven for some days.

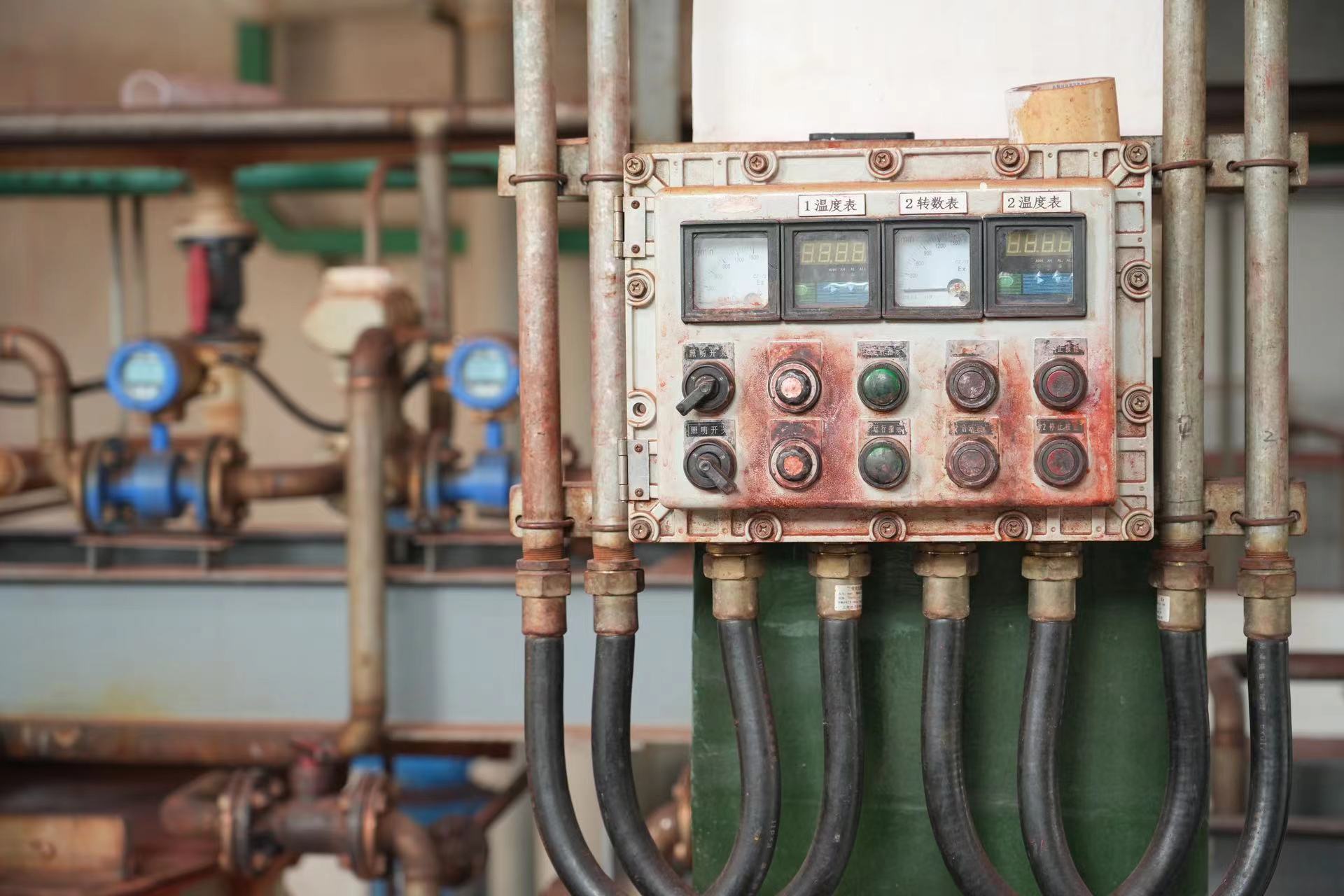

Advanced Manufacturing Equipment

Diazo reaction tank

It plays a crucial role in the production of diazo pigments by providing a controlled and efficient environment for the diazo reaction, enabling us to produce high-quality pigments that exhibit desired color characteristics and stability.

Coupling reaction tank

It's designed to handle a wide range of pigment types including organic pigments and inorganic pigments, it allows for precise control over the mixing process, allow to achieve the desired color intensity, shade, and consistency.

Pressure filtration machine

It helps improve the quality and purity of pigments by effectively removing unwanted particles and impurities. Can achieve consistent and high-quality pigment powders or pastes, which can be further processed and used in various applications.

Drying device

It can ensure that pigments are properly dried, free from moisture or solvents, and ready for further processing or packaging. This helps maintain the stability, color consistency, and shelf life of pigments, enabling their effective use in various applications.

Fabric filter

It's an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. Functioning baghouses typically have a particulate collection efficiency of 99% or better, even when particle size is very small.

Crushing equipment

It's to crush or grind pigments into a fine powder. This is done to enhance the dispersion of the pigment particles in various applications, such as paint, ink, plastic and other color-related industries. By crushing pigments, it helps to improve their color strength, consistency, and overall quality.

Automatic Assembly Line

Commitment to Quality

Fineland is committed to maintaining high quality standards throughout all of our products and services. We continuously improve our manufacturing process and product quality to provide the best product performance and achieve "Zero Defect" in our daily operations.

Our goal is to provide satisfactory and effective customer support, on-time delivery and suitable features at the right price.

- I have some products from other supplier, can Fineland help to arrange the shipment together ?

Yes, no problem. We are happy to be helpful to our client and we are in the position to supply related services such as logistic , quality control, factory inspection .....etc. We can combine the shipment with your other products.

- How long is the lead time of your product?

The lead time for our organic pigments can vary depending on the specific type of pigment and the quantity you require. We can provide you with more accurate lead time information once we know the specific pigment you are interested in and the quantity you need.

Generally, for standard organic pigments that are readily available in our inventory, the lead time can be relatively short, ranging from a few days to a couple of weeks. However, if you require a large quantity or a custom-made pigment, the lead time may be longer to ensure the production and quality control processes are adequately completed.

Details are like this: usually we have regular product stock (2-3mt) in our warehouse near Shanghai. Normally can book shipment within order confirmed 14days. When special product or big quantity we will inform in advance.

Welcome to inquire from us. If you have any specific concerns or additional questions about our product, service procedures, please don't hesitate to ask! We are open-minded to discuss together.

- What's the payment term of Fineland?

Our company offers flexible payment terms to accommodate the needs of our customers. The specific payment terms may vary based on factors such as the order volume, the nature of the business relationship, and other mutually agreed-upon terms. However, some common payment terms we offer include:

T/T (Telegraphic Transfer) or Wire Transfer: This is a common payment method where the customer transfers the payment directly to our company's bank account. T/T is often used for both small and large transactions.L/C (Letter of Credit): For larger orders or international transactions, we may accept payment via a Letter of Credit. With an L/C, the customer's bank provides a guarantee of payment upon the fulfillment of certain conditions.PayPal or Credit Card: For smaller orders or online transactions, we may accept payments through PayPal or credit card, providing a convenient and secure payment option.Western Union or MoneyGram: These methods are sometimes used for smaller or urgent payments.The specific payment term for your order will be discussed and agreed upon during the negotiation process. We aim to ensure a smooth and transparent payment process to facilitate a strong and reliable business relationship with our customers.If you have a specific payment method or term in mind, or if you need more information about our payment options, please let me know, and I'll be glad to assist you further. - If Fineland have agent in our market (customer’s country) ?

At present Fineland only have one factory in China, not develop agent overseas so far. You can directly buy from us, our air and sea transportation also convenient. If you rather buy from local, we can introduce our distributor customers to you.

- Can Fineland help to improve your formula to get better quality performance

Yes, we have customized service, after each other's fully communication, our technical person will adjust the formal and try to match your requirement.

- Which products are produced by Fineland and which are not?We define our company as a comprehensive products and solution provider, since our business covers more than hundreds of different colors , it is not possible and necessary for us to produce all of them.Below are Fineland commonly produced:1. Organic Pigments: these are carbon-based pigments derived from various sources and are often used in the manufacture of paints, inks, plastics, and textiles.2.Inorganic Pigments: Inorganic pigments are made from minerals and metal oxides. Examples include titanium dioxide (white pigment), iron oxide pigments (red, yellow, and black pigments), and chromium oxide green.3. Specialty Pigments: Some manufacturers produce specialty pigments like fluorescent pigments, phosphorescent pigments (glow-in-the-dark), and interference pigments (create iridescent effects).4. Pigment Dispersions:These are concentrated pigment formulations used to color various products like paints, coatings, and inks.Some pigments that may not produced by us:1. Niche or Exclusive Pigments: Some factories may specialize in producing niche or exclusive pigments that cater to specific industries or applications.2.High-Performance Pigments: Certain high-performance pigments, such as those used in automotive coatings or aerospace applications, require advanced production processes and may not be produced by all manufacturers.3. Pigments with Specific Certifications: Some industries may require pigments with specific certifications for safety or environmental reasons. Not all factories may produce pigments meeting those specific criteria.

Fineland Chem —— Professional Organic Pigment Manufacturer

Since 2008, Fineland Chem has been a manufacturer of organic pigments, a well-known brand in the development of innovative color solutions, with a product range of over 100 products ranging from azo pigments to phthalocyanine pigments. Our annual production capacity of more than 10.000 tons can guarantee you a stable supply of organic pigments.

- *Name

- *Tel

- *Title

- *Content